From Idea to Data: How Blackfish Accelerates Innovation with Bespoke Test Solutions

- Sep 2, 2025

- 5 min read

Updated: Sep 3, 2025

At Blackfish, we call ourselves the innovators’ engineer.

It’s more than a strapline. It reflects our role in helping technology developers turn bold concepts into market-ready innovations. For early-stage companies, moving from idea to minimum viable product (MVP) is a daunting journey. It requires not just vision, but disciplined engineering to validate designs, reduce risks, and build investor confidence.

That’s where Blackfish comes in.

The Innovator’s Challenge

Every innovator faces the same hurdle: bridging the gap between simulations and real-world performance.

Mathematical models and FEA can predict how a system should work - but scaling is rarely linear. Physics, friction, and fatigue reveal themselves in ways no spreadsheet can fully capture. Without the right plan, innovators risk missing critical variables, leading to repeated tests, wasted months, and burnt capital.

For start-ups and lean teams, those setbacks can be make-or-break.

The Blackfish Approach

We help innovators map a clear route from idea to data, ensuring every test delivers meaningful results. At the core of our approach is the Verification & Validation (V&V) plan - a framework that defines:

What can be tested mathematically

What must be proven through physical testing

How to progress from components → subsystems → full system

This ensures innovators are not just testing hardware, but answering the right questions at the right time - and building the data investors need to move forward with confidence.

From single components to full system integration, our rigs tackle every scale of challenge.

Four Levels of Engagement

Every client is different. Some need targeted oversight; others need complete turnkey delivery. Blackfish offers four clear pathways - demonstrating flexibility across both advisory and hands-on rig delivery.

1. Advisory & QA

We act as trusted consultants, reviewing plans, providing technical oversight, and catching issues before they escalate. This avoids costly repeat testing and helps lean teams protect their time and resources.

2. Innovation Workshops

Through structured three-day workshops (preparation, collaboration, documentation), we co-develop test specifications with clients. The outcome is a clear, detailed roadmap that maximises the value of testing investment.

3. Design & Fabrication

Where clients need more support, we can assist with the design and delivery of bespoke test rigs and stands, working alongside teams that handle the build in-house or taking full responsibility for fabrication, commissioning, and quality assurance. Some clients prefer to contribute to the build themselves, while others rely entirely on Blackfish to manage every stage of the process.

4. Full Turnkey Delivery

For innovators with lean teams, we deliver the complete package: design, build, commissioning, testing, and final reporting. At this level, clients don’t just receive hardware - they receive validated datasets that accelerate their pathway to market.

Proven Success Across Sectors

Blackfish’s structured approach has already helped innovators accelerate their pathway to market, from renewables to aerospace and academia.

Across sectors, our rigs solve unique challenges - from high-load wind turbine assemblies to delicate fuel cell systems, and from research platforms to fully integrated energy converters.

Whatever the scale or environment, Blackfish rigs provide solutions tailored to each challenge.

SenseWind: Full-Load Testing for 2MW Turbine Assembly

For SenseWind’s 2MW self-installing wind turbine demonstrator, Blackfish developed the Verification & Validation (V&V) plan and delivered the bespoke rig used to validate the main load-carrying assembly. We designed, built, and commissioned the rig, then conducted full-load testing under simulated operational conditions. The results provided the data SenseWind needed to progress their demonstrator with investor confidence.

Full-load mechanical assembly testing for wind turbine demonstrator.

This work gave SenseWind the confidence to advance their demonstrator and showcase a credible pathway towards commercial deployment

Bombora: Air Valve System and Multi-Million Cycle Fatigue Testing

Bombora partnered with Blackfish on the development of their novel mWave device. Our team supported the main cell module design and delivered a new air valve system, proven through scale prototypes and fatigue testing over 5 million cycles. This work combined concept design, analysis, and physical validation, giving Bombora the assurance needed to advance towards full-scale deployment.

Scale prototypes and multi-million cycle fatigue testing, ensuring component reliability.

By validating critical components ahead of scale-up, Bombora was able to progress mWave development with assurance in its long-term reliability

Mocean Energy: Ballast and Generator Integration Testing

Mocean Energy engaged Blackfish to support multiple stages in the development of their Blue X wave energy converter. Our team first designed and delivered a ballast rig to prove the ballasting concept - a system for carefully adding or removing weight (in this case, water) to keep the device stable and level in the water. This ensured safe handling and reliable performance during deployment and testing.

We then went on to design, fabricate, assemble, and commission the full Blue X device itself, taking responsibility for the core structural and mechanical design, integration of internal equipment, and hydrodynamic assessments.

Integration of multiple systems with complementary rigs to validate stability and generator performance.

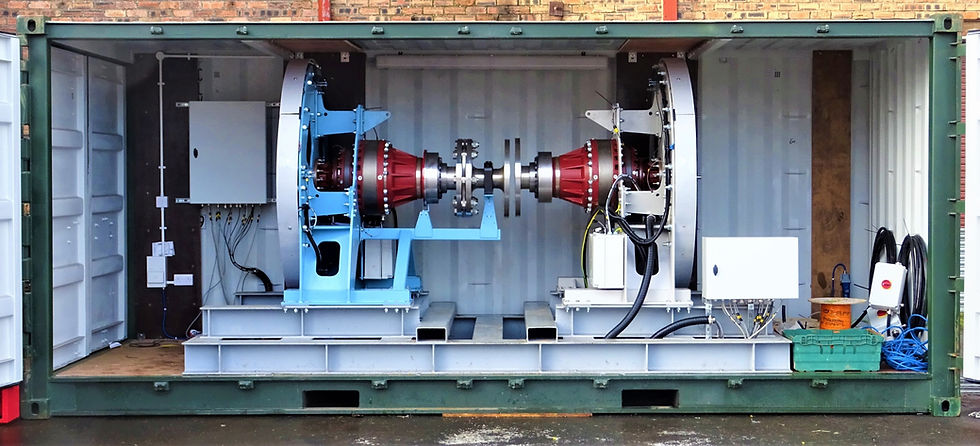

Successfully deployed at EMEC in 2021, Blue X operated for five months in real sea conditions, generating reliable outputs and enabling Mocean to secure over £3 million in follow-on funding for their next-scale device. Alongside this, Blackfish also designed and delivered a back-to-back generator test rig to validate the CGEN modular generator intended for use within Blue X. This provided the critical performance data needed to de-risk generator integration before offshore deployment.

University of Southampton: Advanced Research Platforms

Blackfish partnered with the University of Southampton to deliver two advanced research rigs: a towing tank mooring platform and a pipe flow rig. Designed, fabricated, and commissioned by our team, these facilities now provide the university with reliable platforms for marine and environmental research.

Complex experimental rigs for research and environmental studies.

These rigs now underpin cutting-edge research, enabling the university to deliver reliable data and attract further project collaborations.

Airbus: Dynamic Hydrogen Fuel Cell Flight Testing

In partnership with Airbus, Blackfish developed a hydrogen fuel cell test rig capable of simulating the dynamic conditions of flight. Designed, built, and validated by our engineers, the rig can pitch and roll a 500 kg fuel cell up to 50 degrees, helping Airbus assess hydrogen’s potential for zero-emission aviation.

Dynamic testing rigs for flight conditions, showing cross-sector flexibility.

The project demonstrated how hydrogen fuel cells can be realistically tested for flight, helping Airbus de-risk innovation on their journey to zero-emission aviation.

Beyond Ocean Renewables

While our heritage is in wave, tidal, and offshore wind, the need for robust, early-stage engineering validation exists across many industries:

Energy devices

Hydrogen production systems

Biofuel process equipment

Fusion research programmes

University R&D initiatives

In all these fields, innovators face the same challenge: student prototypes or early models can only go so far. Blackfish fills the gap with professional engineering horsepower, delivering bespoke rigs, intelligence, and data that move ideas forward wherever early-stage innovation demands robust validation.

Whatever the sector or scale, our rigs provide tailored solutions to meet every engineering challenge.

Why It Matters

Every innovation is a race against time. Repeated testing cycles, wasted capital, and missed investor milestones can stall even the best ideas. Blackfish helps innovators:

Reduce technical risk

Avoid wasted costs

Accelerate MVP development

Build investor confidence

Ultimately, we don’t just design test rigs - we design solutions tailored to the unique engineering challenge, whatever the scale, environment, or sector, creating clear pathways to confidence.

Ready to Turn Your Idea into Reliable Data?

Whether you need targeted advisory support, a bespoke rig, or a full turnkey delivery, Blackfish will tailor the right solution to your stage of development.

👉 Contact us today to explore how Blackfish can accelerate your innovation.

Comments